Description

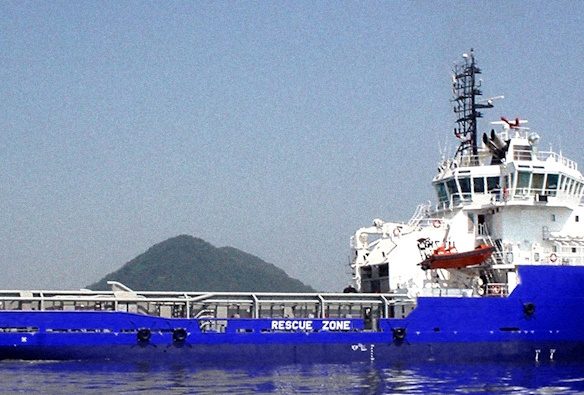

66M DP2 OFFSHORE SUPPORT VESSEL FOR SALE

66M DP2 OFFSHORE SUPPORT VESSEL FOR SALE

Year Built: 2015

PRINCIPAL PARTICULATRS

Length overall: ……………………………67.20m.

Length between pp: ………………………58.90m.

Breadth moulded :…………………………16.00m.

Depth moulded : ……………………………6.50 m.

Design draft: ………………………………5.00m.

Scantling draft: ……………………………5.10m.

Bollard pull: …………………………Min. 96t with main at 100%MCR.

REGISTRATION

Builder: …………Qingdao Yanfan Shipbuilding Co., Ltd.

Flag: …………Singapore

Classification: …DNV. Maltess Cross+1A1 Offshore Service Vessel, SPS,

Clean, DYNPOS-AUTR, E0, Fi-FiⅡ COMF-V(rating3), TMON, Rcycable ,

BIS for unrestricted service.

Regulation: …..SOLAS, Marpol, IMO A 469 (XII).

PERFORMANCE SPEED

Min. 13 knots at 100% MCR

ENDURANCE Min. 25 days

ACCOMMODATION

Captain’s Deck

5×1MAN=5MEN

Deckhouse Deck

1×1MAN=1MAN

4×2MAN=8MAN

4×4MEN=16MEN

Forecastle Deck

4×4MAN=16MAN

1×2MEN=2MEN

2×3MEN=6MEN

Total 54MEN

PROPULSION – MACHINERY

Main diesel engines: 2×2666KW

Shaft generators: 2×1200KW, 440V/60Hz

Auxiliary generators: 3×550KW, 440V/60Hz

Emergency generator: 1×150KW,440V/60Hz

Main propellers: 2×CPP

Tunnel thrusters aft: 2×500KW

Tunnel thruster forward: 2×950KW

Rudders: 2×off high lift flap rudder

TOWING/MOORING WINCH

Anchor: 2×AC-14 high holding power anchors, each min. 1845 kg

Chain cables: 467.5M total length, 44mm dia. Grade 2 high strength

stud link chains.

Mooring lines: 4×170m long mooring rope of minimum 186kN breaking

strength

Towing wire: 1×190m @ 479kN breaking strength

Anchor Windlass:

Duty pull: 12.4t at 0 to 21m/min

Gypsy size: suitable for 44mm dia. U2 high strength stud line chain.

Chain stopper: suitable for 44mm dia. U2 high strength stud line chain.

Brake control: manual operated band brake

Gypsy clutch: manual operated jaw clutch

Mooring Storage Drum:

Drum capacity: 220m×64mm P.P tope approx.

Duty Pull: 15.8t at 0 to 18 m/min (1st layer)

: slack rope at 0 to 69 m/min

Brake control: manual operated band brake

Drum clutch: manual operated jaw clutch.

Mooring Bollards

Bollards:10×10” NB sch 80 heavy pipe bollards

Mooring Posts/Closed Chocks: 6×mooring pipes & 3×closed chocks , 300×400

Stand Roller: 6×250 mm dia. & 2×200mm dia. Fair lead-open type stand rooler

Towing Pins: 2×200 tonnes SWL

Shark jaws: 2×11/4’’ to 4’’ dia. Wire and chain. SWL 300t

Capstan: 2×variable speed hydraulic capstan

Duty pull: 10 t @ 0 to 18 m/min

: lightline speed @ 0 to 19 m/min

Tugger Winch:2×variable speed hydraulic Tugger

Duty pull: 10 t pull @ 0 to 24 m/min

: 3 t pull @ 0 to 75 m/min

: lightline speed @ 0 to 97 m/min

Storage Rope Reel: 1×variable speed storage rope reel

Duty pull: 7 t @ 0 to 75 m/min

: lightline speed @ 0 to 127 m/min

Electric-Hydraulic power pack for Deck Machinery: 3×electric hydraulic power pack

CAPACITIES & PUMPS

FW/DW/SWB tank: …………700M3 approx.

FW tank: ………………………420 M3 approx.

F. O. tank: …………………… 590 M3 approx. ……Pump2×20 M3/h

F. O. overflow tank: ……………18 M3 approx.

Cement tank: ……………………215 M3 approx.

Liquid mud/Brine DW tank: …350 M3 approx. …Pump2×100 M3/h

Brine/DW/SWB tank(or rig chain locker):…150 M3 approx.

Lub oil: …………………………12 M3 approx.

Dispersant tank: ………………15 M3 approx.

Sewage holding tank: …………16 M3 approx. …… Pump1×15 M3/h

Bilge holding tank: ……………7 M3 approx.

Dirty oil tank: …………………8 M3 approx.

Hydraulic oil tank: ……………7.5 M3 approx.

ELECTRONICS

2×radar 96NM X-band

3×gyrocompass system with repeaters

1×echo sounder

1×speed log

1×GPS

2×DGPS

1×radio system compliant with GMDSS A3 rules

DP SYSTEM (class II)

ERN NUMBER:99,99,96,96

SPECIAL EQUIPMENT:

FIFI Ⅱ: 2×3700 M3/h

Liferafts: 4×25men & 4×20 men inflatable liferafts

Rescue/Workboat: 1×semi rigid type rescue boat

1×40HP long shaft motor capable of carring 6 persons & 1×1.65t SWL remote

operated davit for lifting and lauching

Cranes: 1×electro-hydraulic & luffing deck crane, 3t. at 10m radius

The vessel is designed and built as an offshore support vessel, which has

twin screw with controllable pitch propeller, two (2) bow/ two (2) stern

tunnel thrusters and two (2) station controls in wheelhouse. Two main diesel

engines with 2×2666kw totally.

Bollard pull is no less than 96t at 100%MCR. Performance speed is no less

than 13 knots at 100% MCR.

It is classed to DNV and satisfy external FI-FIⅡ class &Dynamic positioning

Ⅱrequirement.

It can transport liquid cargo, bulk cement, liquid mud, stores,

materials & equipment, also can perform towing & anchor handling duties.

It can be a salvage vessel, do a service for seabed oilfield which has

production platform, equipped with device for fire fighting, salvation etc..

This vessel has the advantages of large power, good sea-keeping performance,

excellent manoeuvrability, advanced equipment. Its technology is in the

highest flight across the world.